From building customer confidence to upskilling employees to optimize their work, this Cobot Clients blog post looks at the collaborative robot journey of Continental, India, from the perspective of Mr. Amar Burud, Senior Manager – Industrial Engineering.

The Background

Continental is one of the world’s largest tire manufacturers. Before, their manufacturing plants consisted of machines handled by operators. The jobs were highly repetitive in nature, making the operators prone to fatigue and many ergonomic risks. This in turn used to result in many human errors, slowing down the production lines and failing to meet the high standards of quality Continental strives to achieve. The company was also plagued with many machine breakdowns due to these issues.

Enter the Cobot

The automotive giant deployed a collaborative robot 3 years ago and integrated it with their machines, which were previously operated on by their employees. Amar found cobots to be a much more convenient solution than traditional robots due to many reasons. For starters, thanks to the collaborative nature of cobots, the Continental team did not have extra expenses to acquire protective fencing or safety curtains, which are a must for traditional robots. Installing a traditional robot meant that the additional accessories that came with it would bring more problems than solutions.

"Cobots did not require any of these extra accessories as they could perform all of their actions within the same vicinity of our employees. We didn’t have to worry about the safety of our workers. We also found that the maintenance costs of the cobot was much lower than that of a traditional robot.’’

~ Amar Burud, Senior Manager – Industrial Engineering, Continental India

Crafting the Perfect Cobot Solution

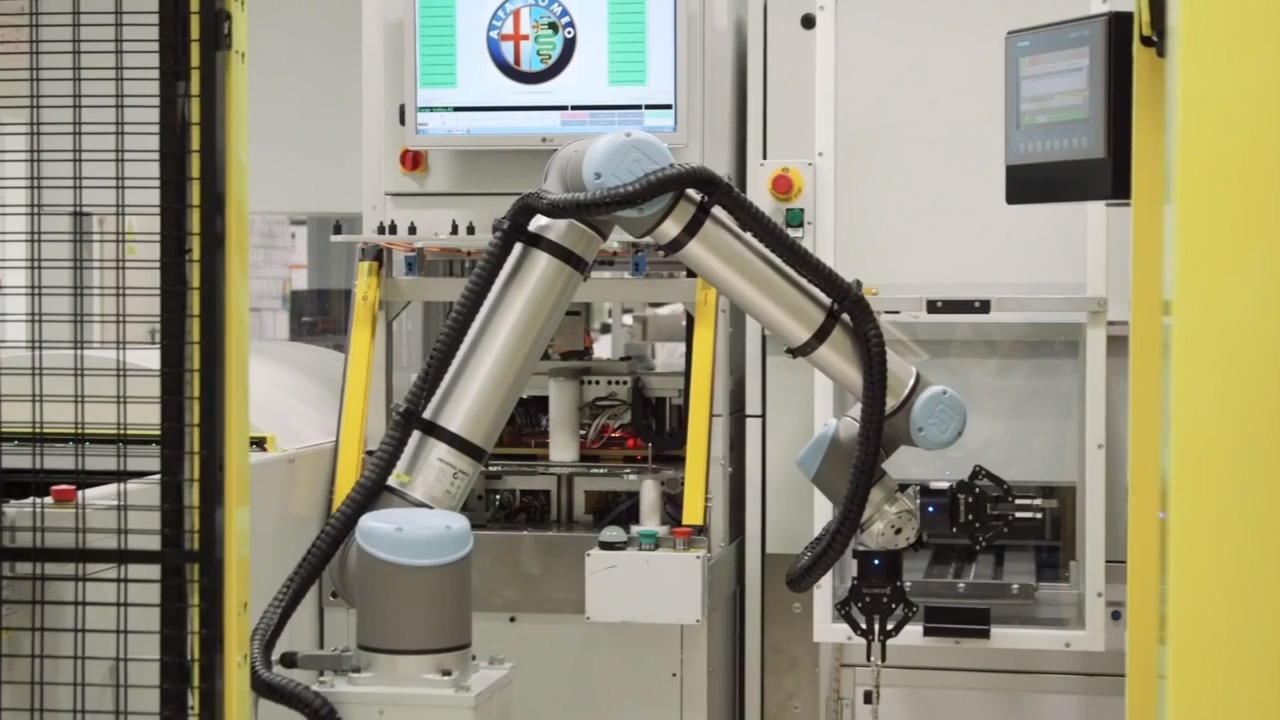

Image: Collaborative Robots at Continental Automotive, Spain

Image: Collaborative Robots at Continental Automotive, Spain

Continental’s decision to deploy a cobot 3 years ago proved to be beneficial for all of their needs. The installation of cobots made production easier and quicker, and re-assigning them the tedious and repetitive jobs improved the quality of the company’s production greatly.

"Once we installed a cobot and integrated it with the machines, our downtime went to almost zero. This was one of the most beneficial achievements for us, as the productivity levels improved massively.’’

~ Amar Burud, Senior Manager – Industrial Engineering, Continental India

The manufacturing giant found the integration of cobots in their factories an easy and convenient job, as UR cobots were supportive in every way – they could be used to automate almost any application. Their flexibility allowed them to use the cobot for a multitude of functions – the way the cobot was used depended solely on the user. Be it for simplex or complex applications, it could be integrated with all of their machines to perform any task required.

“We like to integrate functions in a simple way, with any resources that we have available. Once we deployed the cobot, we found that it could perform any task with whatever inputs that were present. We found it very helpful that we could integrate the cobot with a number of applications’’

~ Amar Burud, Senior Manager – Industrial Engineering, Continental India

Amar also found that the cobot itself was easy to deploy and use. Despite this being the first cobot ever installed in their facility and employees not having prior robot programming experience, the Continental team was able to learn how to safely operate the cobot within a day for their daily tasks.

Interactive Customer Visits

Cobot installations at the Continental plant awed their customers, who could now watch the cobots perform tasks with absolute precision, making their visits even more impressive and interactive. By watching and experiencing the level of automation that took place, customers became even more convinced about the quality and reliability of the products. With the help of cobots, the quality of manufacturing skyrocketted and Amar says that their customers could notice that as well.

“We have installed many cobots in our organization and they really do attract customers during visits. Our customers watch the movements of the cobots, making these visits more interactive. It builds confidence amongst them about the quality of our products.’’

~ Amar Burud, Senior Manager – Industrial Engineering, Continental India

Cobots Upskill Everyone

Cobots were not just helping Continental in their production – they were also playing a massive role in creating higher valued jobs by upskilling their employees. Being collaborative in nature, they work alongside humans and not replace them. By taking over the dull, dirty, dangerous and repetitive tasks, cobots allowed the workers who were previously assigned those tasks to showcase their skills in other areas that were more valuable.

“Our employees could not show who they really were when they were performing repetitive and dull tasks. These workers were very skillful in other areas, and by letting cobots take over the job, they could upskill themselves and demonstrate themselves in other areas – and they were happy to do it!”

~ Amar Burud, Senior Manager – Industrial Engineering, Continental India

Deploying collaborative robots thus proved to be beneficial for almost all sectors of the company. Employees could now work in areas which required different skills, leaving behind the low valued tasks that put them at risk of health and safety concerns.

The Reliability of Universal Robots

For Continental, quality always comes first and that’s what the cobots delivered. Around the year, high demands call for high levels of productivity, but before cobots entered the picture, the company was unable to reach its full manufacturing potential due to the stringent nature of crucial tasks. By turning to Universal Robots and deploying a cobot, their workers were relieved of fatigue and ergonomic risks, resulting in no hindrances in their production.

“For us, our highest priority is always quality. We knew that fatigue decreases the efficiency of operators. We were also facing internal rejections. Choosing Universal Robots as our first option was the best decision for us, because we could meet the desired quality levels without having to put our operators at risk – the quality and efficiency are both moving upwards!”

~ Amar Burud, Senior Manager – Industrial Engineering, Continental India

Amar spoke about having a great experience with the UR team and their partners. Even though this was the first time Continental India had installed a cobot in their facility, they found the team very supportive and helpful regarding any issues – from pre-installation to post-installation.

“Team Universal Robots was always there to support us in any form. They did not care about the complexity and difficulty of the application. They came forward to try and help us out to make sure the application is up and running. Even after the cobot was installed, the team was always there to help us.”

~ Amar Burud, Senior Manager – Industrial Engineering, Continental India

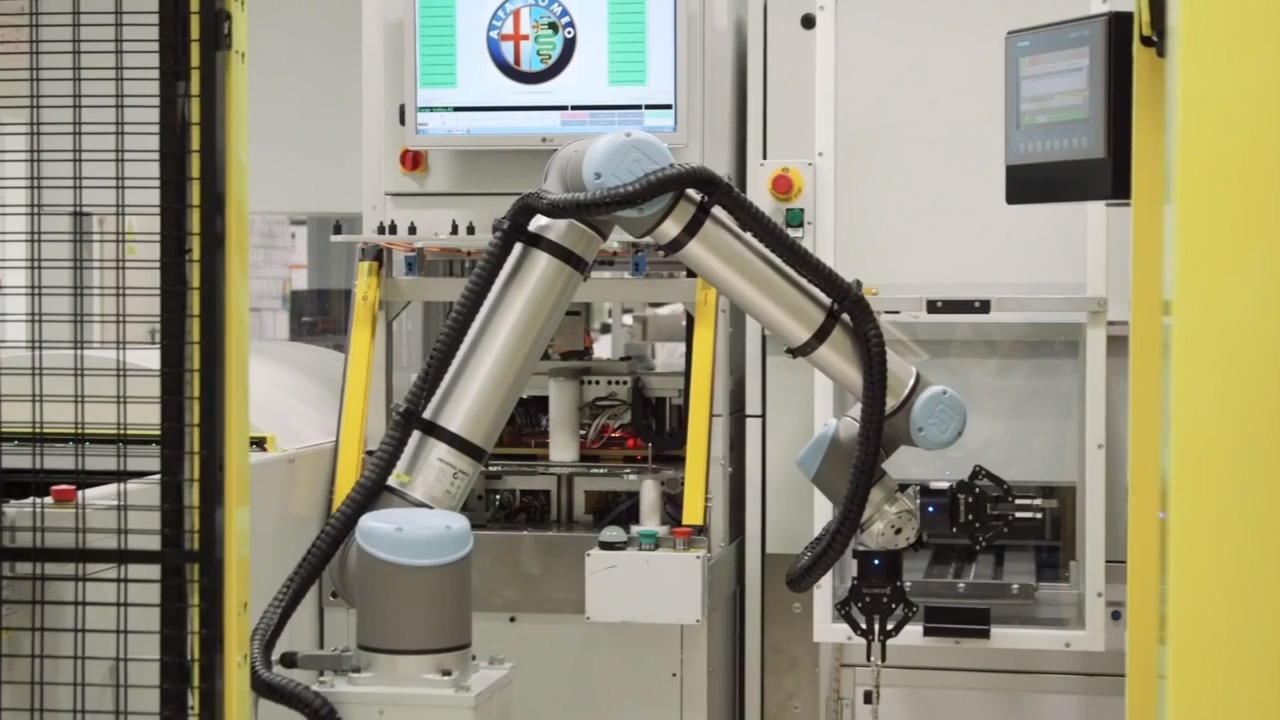

Image: Collaborative Robots at Continental Automotive, Spain

Image: Collaborative Robots at Continental Automotive, Spain

Comments