GET REMOTE ACCESS TO YOUR UNIVERSAL ROBOT

What if we could always get in touch with our UR robots, anywhere, anytime - from any device?

That was the question Airgate, a Danish developer of customized IoT solutions, often encountered when talking to distributors and end-users of UR robots.

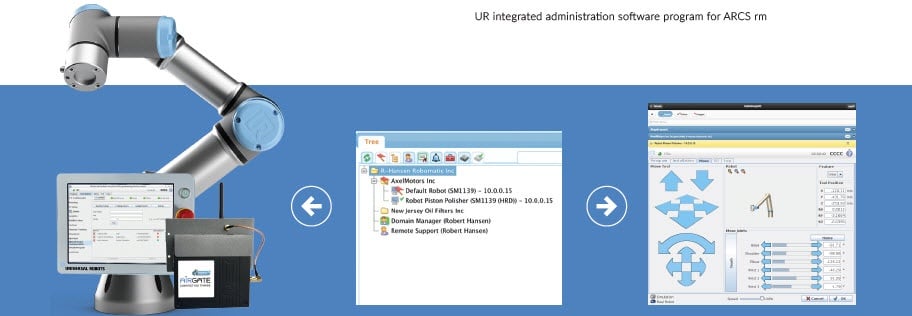

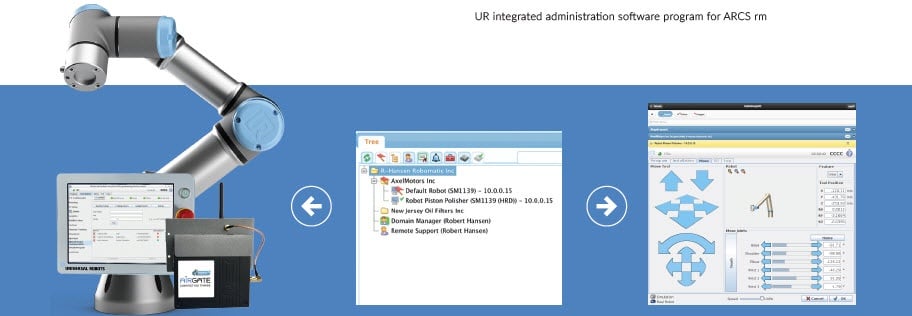

Airgate had developed a GSM modem solution, ARCS basic, that provides simple remote monitoring of the UR robots by sending text messages to the robot operator when the robot exceeded defined limits such as running out of material or stopping work unexpectedly.

But one thing is getting an alert, another is actually being able to access the UR robot’s own PolyScope interface remotely to manage; troubleshoot, operate, diagnose and avoid critical downtime.

“We discovered a need in the market to take our products to the next level and provide a solution that assists the robot operators on the floor from a central support function,” says Airgate’s CEO, Søren Lund, explaining that the remote support would typically be from an in-house supervisor, a distributor, or even UR’s own tech support.

The additional solution, ARCS rm - also certified by UR and available through the Universal Robots+ showroom - is software that provides an encrypted VNC connection between the robot and any internet-connected device that the robot owner has granted access to. Once the connection is established, the PolyScope GUI on the robot’s touch screen will stream to the connected device screen.

“Instead of the robot supporter having to travel on-site, perhaps spending a whole day on this, it’s now possible to diagnose and remotely operate immediately, minimizing costly downtime both for the end-user and the support provider. Our product could easily pay itself back in a single day,” says the Airgate CEO.